Few bearing types offer the overall lifetime value in demanding radial loading applications as provided by cylindrical roller bearings. Their unique design and exceptional engineering make them the go-to solution for technologically advanced applications with stringent operating conditions. In this article, I want to discuss the features of cylindrical roller bearings, particularly their structure, mode of operation, and contribution to optimizing the operation under radial loading. This guide is intended for those interested in the progress in the engineering field and its impact on industries. Bearing engineers work tirelessly to improve operational efficiencies and achieve new frontiers of mechanical engineering automation and innovation, and this guide shows how these bearings help accomplish that.

What are cylindrical roller bearings, and how do they work?

Understanding the structure of cylindrical roller bearings

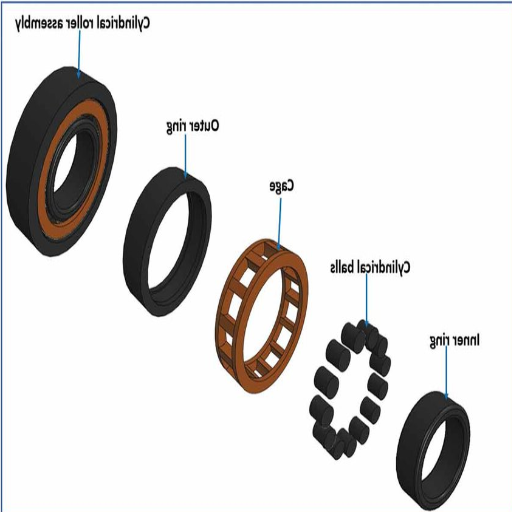

Cylindrical roller bearings are carefully manufactured components that help handle large radial loads. Their configuration includes typically inner and outer rings, cylindrical rollers, and cages that support and guide the rollers. Unlike ball bearings, the rolling elements in cylindrical roller bearings have linear contact with the raceways, leading to better load distribution and lower stress concentration. This improves their ability to support large weights and bear shocks.

Roller Diameter and Length: The size of the rollers affects the load-carrying capacity. Rollers with larger diameters can bear greater radial loads.

Number of Rows: There can be single-row, double-row, and multi-row bearings, where additional rows provide more load capacity.

Clearance: Radial internal clearance, the distance measured between the rollers and raceways, is changed relative to the working conditions to achieve optimal performance.

Material Composition: These bearings usually comprise high-grade steel to resist wear, corrosion, and deformation from heavy loads and high speeds.

Speed Rating: This value is defined by the maximum limit of allowable rotational speed and determines the applicability of the bearing for specific tasks.

With these elements properly located, cylindrical roller bearings provide reliability and low friction in advanced mechanical systems.

How cylindrical rollers distribute radial loads

Due to their specific structural attributes, cylindrical roller bearings can effectively manage radial loads. Ball bearings, with their higher stress concentration, are better suited to rest under load. This reduces load-bearing stiffness for heavier or shock-load applications, but cylindrical roller bearings outperform in load-bearing capacity.

Contact Area: High pressure leads to deformation, but the linear contact between the roller, the raceway, and the roller enables increased area distribution, leading to less deformation.

Load Rating (C): Cylindrical roller bearings usually have a high dynamic load rating, which increases their ability to sustain significant radial loads over extended periods.

Rigidity: Deflection under load and precision poses a challenge for some applications, but the bearing’s increased stiffness due to roller geometry allows it to overcome this challenge.

Misalignment Tolerance: Although cylindrical roller bearings are highly proficient in radial load applications, they are ineffective with angular misalignment, which requires precise installation.

These technical attributes ensure accuracy and reliability alongside durability for heavy-duty mechanical systems.

Comparing cylindrical roller bearings to ball bearings

The examination of cylindrical roller bearings and ball bearings should be accomplished from the perspectives of function and configurational components:

Load Capacity:

Cylindrical Roller Bearings: With their wider contact area due to the rollers, these bearings are built to support high radial loads and are suitable for heavy-duty operations.

Ball Bearings: These bearings typically take radial and axial loads but can work under low radial loads better than cylindrical roller bearings.

Speed Capability:

Cylindrical Roller Bearings: These bearings usually work at lower speeds because of the considerable friction caused by the rolling elements. Their speed is limited, but it is less than the limit of ball bearings.

Ball Bearings: Because of their lower friction, these bearings work well at northern speeds and are employed in all high-speed work.

Misalignment Tolerance:

Cylindrical Roller Bearings: They do not tolerate angular misalignment of any sort. Their design offers and insists on rigid alignment, meaning accurate mounting is necessary.

Ball Bearings: These are capable of any degree of minor misalignments. Hence, they are relatively easy to work with when installing and operating.

Applications:

Cylindrical Roller Bearings are often found in heavy machines, electric motors, and gearboxes that need good support and durability under intense radial loads.

Ball Bearings: Ball Bearings have a wide range of applications in automotive, aerospace, and industrial machinery where moderate loads and high speeds are carried out.

An engineer can find an optimal solution for using either ball or roller bearings by analyzing the application parameters, such as load type, speed, alignment, and efficiency, in detail.

Why are cylindrical roller bearings suitable for high radial load applications?

Exploring the high load capacity of cylindrical roller bearings

With their structure and mechanics, cylindrical roller bearings can carry enormous radial loads. Their rollers are in line contact with the raceways, and compared to the point contact of ball bearings, the loads are distributed over comparatively larger areas. This design reduces stresses and deformations while working under heavy loads, making it ideal for rigid applications.

Load Capacity: Due to the linear contact between the rollers and raceways, cylindrical roller bearings have a high radial load capacity. Compared to other bearings, they sustain loads considerably greater than ball bearings of equal dimensions.

Speed Rating: While acceptable for moderate to high speeds, the speed performance is usually less than that of ball bearings because of greater friction produced by the larger contact surface. Depending on the lubrication, the bearing design also has speed rating features.

Axial Load Capacity: In these types, depending on design (e.g., NU, N) do not support axial loads, they have limited or none at all.

Misalignment Tolerance: Stress caused by misalignment tends to be high. Therefore, the tolerance is set low to prolong the bearing life.

Size Variations: These are provided in several configurations, such as double-row or single-row patterns. Each has rollers of different lengths and diameters designed to meet specific requirements.

Cylindrical roller bearings have unique attributes that make them suitable for applications such as heavy radial loads in industrial machinery, electric motors, and gearboxes. These highly reliable applications require long-term durability, which is critically essential. The type and size of the bearing selected must be appropriate to ensure optimal performance.

Analyzing the linear contact between rollers and raceways

One characteristic that defines the cylindrical roller bearing is the linear contact between the rollers and the raceways. This type of configuration permits high load-carrying capacity with lower stress concentration so that there is a more straightforward incorporation of load along the surface of the roller. This will reduce the rate of wear and increase the life of the bearing. In this case, other parameters will be used for the description and optimization of the linear contact, such as:

Contact Stress is a function of the applied load, roller diameter, and the curvature of the raceway. To decrease deformation and stress, the right choice of materials and heat treatment is needed.

Load Distribution: The line contact creates a uniform load along the roller and raceway, minimizing local stress concentrations in point-contact systems like ball bearings. The load capacity must be matched reasonably to the application’s requirements.

Roller and Raceway Surface Roughness: For most industrial applications, roughness is a critical variable measured in Ra, μm, where smooth surfaces yield lower friction and reduce wear. Surfaces with roughness from 0.1 μm to 0.3μm are ideal.

Misalignment Tolerance: The movement of the casing relative to the rotation axis should provide a position located equally for the contact of the rollers and raceways. The misalignment tolerance is usually in the region of 4 angular minutes for cylindrical roller bearings.

Lubrication: Proper lubrication helps reduce friction, avoid overheating of the contact surface, and prevent negative impacts from wear and tear. Usually, viscosity classes (ISO VG 32-150) are set for operating speeds and loads.

Through strategic analysis and implementation of these parameters, the reliability of cylindrical roller bearings in harsh operating conditions can be improved by considerable margins.

Examining the radial rigidity of cylindrical roller bearings

Radial rigidity is essential in applications like those in which cylindrical roller bearings are incorporated because of their precision and stability under loads. It ensures low deformation as well as robust performance under radial forces. To evaluate radial rigidity, consider the following dimensions:

Contact Area and Roller Configuration: The enhanced contact area between rollers and the raceway increases rigidity. For two designs of full complement caged and uncaged cylindrical roller bearings, the former is generally more rigid.

Material Elastic Modulus: High-grade steel or ceramic materials with high elastic modulus increase the bearing’s rigidity and reduce deformation under stress.

Clearance Settings: Radial clearance is characterized by internal displacement within a system. Minimizing it while achieving additional precise alignment boosts rigidity. Based on thermal expansion and load conditions, standard clearance classes (C2, CN, C3) should be selected.

Load Distribution: Effective prevention of localized stresses due to modified inner and outer rings leads to contribution in rigidity due to uniform load distribution.

The parameters stated above, and their careful selection is bound to optimize exceptional radial rigidity while simultaneously accommodating the bearings to advanced requirements.

What types of cylindrical roller bearings are available for different applications?

Single-row vs. double-row cylindrical roller bearings

The single-row cylindrical roller bearings are meant to perform precise direct work on radial loads with unilateral thermal expansion. Their applications are moderately loaded and compacted assemblies. The principle bolts characteristic for single-row bearings are: small footprint, limited axial loads, and max radial loads defined by the number and size of the rollers.

Because of the additional row of rollers, double-row cylindrical roller bearings have better performance radial loads carrying capacities. This feature enhances bearing stiffness; hence, these bearings are more suitable for higher radial loads and applications with minimal axial deflection. Enhanced parameters for these double bearings include more extensive load ratings, superior rigidity, and advanced ability to distribute loads across the roller contact paths.

When choosing between load capacity, spatial restrictions, and operational accuracy, requirements for load capacity, spatial restrictions, and operational accuracy should be evaluated to ensure precise performance.

Full complement cylindrical roller bearings: When to use them

Full-compartment cylindrical roller bearings can be the best option when heavy radial loads need to be accommodated, but due to space constraints, bearings with cages cannot be used. Without a cage parameter, these bearings can accommodate a greater number of rollers, which increases their load-carrying capacity. They are best for operations at low or medium speeds since the absence of a cage could increase friction at higher speeds.

Load capacity: The maximum number of rollers in the bearing significantly increases the radial load capacity.

Speed limitations: There is some friction due to direct contact between the rollers, which suggests a moderate speed range capability.

Rigidity: A greater contact area leads to greater structural rigidity, contributing to the bearing’s stable performance under heavy loads.

Space efficiency: Suitable for space-constrained applications due to compact design and the lack of a cage.

These bearings can be used in heavy-duty industrial machinery, such as presses, construction gear, or the transmission systems of heavy vehicles. They are best suited for applications with enhanced load capacity and compact design. Balancing load requirements with speed and lubrication parameters to achieve the best results.

Tapered roller bearings: A variation for combined radial and axial loads

Tapered roller bearings are unique components that can sustain radial and tangential loads, enhancing their utility within different sectors. The internal design consists of tapered inner and outer raceways combined with rollers. These raceways permit the rollers to taper towards a point. This shape promotes effective load distribution, hence minimizing the stress concentration.

Contact angle: The contact angle ranges from 10° to 30° and determines the radial loads that the bearing can sustain. The larger the angle, the greater the axial force that can be sustained in the bearing.

Dynamic load rating (C): The rating defines the bearing’s capability of withstanding dynamic loads in motion, rated in kilonewtons (kN).

Static load rating (C0): The kN rating defines the bearing’s ability to withstand sitting loads without change in form (deformation).

Speed limitations are governed by the type of lubrication, load conditions, and the maximum high speed, which the maker usually specifies.

Material strength: Steel alloys are frequently used in components due to their considerable strength at high stress and temperature.

Tapered roller bearings are used in construction machinery, automotive wheel hubs, and gearboxes, especially where combination load control is essential for proper functioning. The choice of tapered roller bearings is based on the usual estimation of the load directions, environmental considerations, and operational speeds.

How are cylindrical roller bearings designated and selected?

Decoding cylindrical roller bearing nomenclature

Understanding the sequential codes provided by manufacturers from angles I consider important regarding the bearing type and series is critical to ‘Decoding the cylindrical roller bearing nomenclature.’ These codes, as I know, consist of numbers and letters that illustrate the distinctive attributes of the bearing.

Bearing series and kind: The preliminary digits or letters comprise the bearing series, which specifies the type and dimension. For instance, “N”, “NJ”, or “NU” describes the configuration of the rollers and raceways making it possible for the bearing to support axial or radial loads.

Inner diameter (ID): The following segment of the code indicates the inner diameter of the bearing in millimeters, which is generally a multiple of five. Based on my experience, “04” denotes a 20 mm inner diameter. This value greatly aids in guaranteeing accurate shaft fitment.

Window modification and clearance: Further letters or numbers usually correspond to modifications of the internal design or a radial internal clearance such as “C3” which means there is an allowance for an expansion under high speed or load, hence greater internal clearance is used.

Materials and substantive coatings: Other coded elements provide information about specific treatments, such as heat and anti-corrosion protective coatings, which are relevant in extreme conditions of high temperatures or moisture that can severely damage expected deployment functionalities.

If I encrypt these designations appropriately, I’ll identify the matching loading capacities, rotational speeds, and the environment’s compatibility. In this case, the allowances must suit the application’s needs to achieve maximum performance with minimum wear and tear.

Factors to consider when choosing the correct cylindrical roller bearing

In choosing the most suitable cylindrical roller bearing, I look at different factors to ensure a proper fit and function. Measurements of load to be supported: I look into whether the bearing has to support radial and/or axial and/or a combination of both types of loads. This will directly affect the technical aspects, such as the capacity of the bearings and the strain being allocated over the equipment, such as rollers. For example, if there is a need to support high loads, it becomes necessary to increase the size of the reinforcing structure or the roller itself.

Speed ratings: Checking how fast the machinery operates is the other crucial element that, if not obeyed, could lead to a situation where the bearing exceeds its set speed, leading to overheating, wear, and ultimately, a drop in the lifespan of the machinery. I choose bearings with a speed rating equal to the required operational levels.

Alignment tolerance: I choose a more excellent range of flexibility if there is a possibility for misalignments because the range within which such an area can be misaligned will cause a non-uniform distribution of loads and, therefore, different types of wear in different bearing positions and regions.

Environmental factors: In severe environments, bearings must be heat-resistant, sealed units, and coated with anti-corrosion material. However, operating conditions, such as temperature, moisture, and other contaminants, must also be considered.

Internal clearance determines a bearing’s ability to tolerate thermal expansion or high-speed loads. A bearing with “C3” clearance is more applicable when a higher thermal threshold is required.

Considering these considerations, I ensure that the bearing selected meets the application’s technical requirements of strength, effectiveness, and ecological fitness, which are essential for sustainable functionality.

What maintenance practices ensure optimal performance of cylindrical roller bearings?

Proper lubrication techniques for cylindrical roller bearings

Proper lubrication is crucial for the efficiency and durability of cylindrical roller bearing operations. I always select the type of lubrication, whether grease or solid lubricants, according to the application and operating conditions. These parameters include speed, load, temperature, and environmental exposure. Grease works best at moderate speeds and loads, but oil has an advantage over grease in high-speed or high-temperature environments because it dissipates heat more effectively.

With proper lubrication, I also consider maintaining volume, as it is central to any lubrication practice. Over-lubrication leads to excess friction and heat, while under-lubrication results in surface wear due to inadequate film strength. Another vital practice is regularly monitoring and replenishing the lubricant per the manufacturer’s maintenance schedule. Doing so ensures the bearing works efficiently under different conditions. Following these practices and considering the technical parameters provides consistency in performance and minimizes the chances of premature bearing failure.

Monitoring and preventing common cylindrical roller bearing failures

My circular roller bearing failure identification and correction strategies concentrate on proactive maintenance and routine bearing inspection. Using an infrared thermometer and a vibration analyzer, I monitor wear indicators, including noise, vibrations, and temperature. These parameters tend to indicate an underlying problem with bearing alignment, contamination, or lack of lubrication—three critical issues for bearing functionality.

In the event of contamination, I ensure that seals are tightened and always replace broken seals. Contamination decreases the strength of the lubricating film, increasing the chances of surface damage and abnormal wear. I check the lubricant type and the amount of lubricant applied to the part for lubrication failures. I ensure it meets the operational requirements and that all relevant speeds, loads, and temperatures are accounted for. I also check alignment and shaft support to prevent misalignment that creates localized stress on the bearing and causes bearing fatigue over time.

Addressing these factors systematically allows me to maintain performance target levels with minimal downtime and increased service life for the cylindrical roller bearings.

Frequently Asked Questions (FAQs)

Q: In what aspects do cylindrical roller bearings excel compared to others regarding radial loads?

A: Compared to others, cylindrical roller bearings have a range of competitive advantages, such as the ability to withstand an impressive radial load and unmatched radial rigidity. Their extensive ability to operate under heavy radial loads renders them perfect for applications where massive radial forces are inevitable. Moreover, these bearings permit low friction operation, which is critical for machine and energy efficiency.

Q: Name some common examples of heavy machinery that employ cylindrical roller bearings.

A: Besides machine tools and heavy machinery, cylindrical roller bearings have proven helpful in gearboxes and other industry sectors. They are, however, more suitable for rolling mills, industrial pumps, and paper machines, which require ultra-high radial load and precision.

Q: Compared to other types of bearings, how do cylindrical roller bearings differ from the rest?

A: Besides other bearings, cylindrical roller bearings stand out the most for their astonishing load capacity. They outperform their competitors with similar dimensions as ball bearings and are heavily adopted compared to spherical roller bearings when radial loads are predominant. As a result, they are regularly employed where minimal space is available, but excellent load capacity is still needed.

Q: Do cylindrical roller bearings support axial loads?

A: In general, cylindrical roller bearings are suitable for radial loads but bear some capacity for axial loading in one direction. Generally, bearings with an associated axial load will always have a lesser capacity than radial ones. When there is considerable axial force, using different types of bearings is prudent.

Q: What are the various classifications of cylindrical roller bearings?

A: Cylindrical roller bearings come in different forms, such as single-row or double-row bearings, with some variations designated as NU, N, NJ, and NUP for single-row bearings and double-row. The choice is guided by what the problem or application needs. Take, for example, NU, NU-type bearings, which permit movement of the shaft in the direction of the housing, while NJ-type bearings aid in movement and permit some axial loading unidirectionally.

Q: How are the cylindrical roller bearings marked?

A: The marking of bearings is done within a framework of the type of bearing, its series and type number, and dimensions. A type marking and a dimension series marking show the letter, which provides the bearing type, as in NU, N, NJ. Further digits set out the dimension series as well as the diametral hole. The presence of some symbols marks unique characteristics or changes.

Q: What is the purpose of the cage in cylindrical roller bearings?

A: The cage maintains adequate separation between the rollers; it helps reduce friction between the rollers and aids in the smooth functioning of the bearing. In addition, the performance of the bearing may be influenced by the design of the cage, especially in high-speed cases.

Q: How do cylindrical roller bearings affect the performance of machine tools?

A: The machine tools that use these bearings are more rigid radially. This is important because these tools need to maintain precision and accuracy during machining operations. Their ability to deal with large radial loads while allowing for high speed rotation makes them suitable for spindle supports and critical parts in machine tools.

Q: What are the maintenance issues to be looked after for cylindrical roller bearings?

A: Roller bearings must be adequately lubricated to maintain performance and longevity. Regular inspection for wear, alignment, and dirt is also critical. Some of the bearings need to be replaced in cycles to keep the machine’s peak performance at all times. Specific procedures are best laid out using SKF instructions, which give a particular maintenance order to follow.