Welcome to our blog dedicated to exploring the world of long life cylindrical roller bearings. In this series, we will delve into the innovations and technical advancements that make these bearings essential for high-capacity and long-life applications. Our articles will cover a variety of topics including the engineering principles behind their design, the materials used in their construction, and the unique benefits they offer in different industries. Whether you’re a seasoned engineer or simply curious about mechanical components, this blog aims to provide comprehensive insights and practical knowledge for better understanding and utilizing long life cylindrical roller bearings.

What is a Cylindrical Roller Bearing?

Definition and Characteristics of Roller Bearings

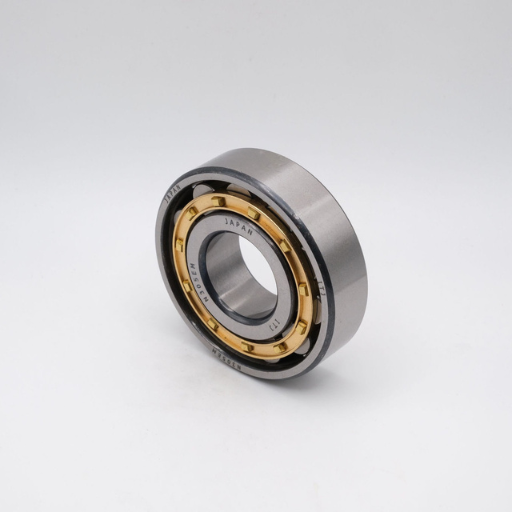

Cylindrical roller bearings are specifically designed and employed in separation of moving components by means of cylindrical rollers. Almost all roller bearings utilize spherical balls in place of cylindrical roller son structural design however; cylindrical roller bearings are reported to take more radial loads than ball bearing due with the wider area of contact between rollers and the raceways. These comprise an inner race, an outer race and a plurality of cylindrical rollers each with one of the races mounted with ribbed guides. The major attributes of cylindrical roller bearings are high radial load, light friction and high speed performance. In addition, the single-row and multiple row configurations for such bearing enable adaptation when it comes to the requirement for load and speed, thereby facilitating a variety of industrial based applications.

Types of Cylindrical Roller Bearings: A Comprehensive Overview

The most common bearing smaller in overall size compared to other bearing types employed in applications is a type of cylindrical roller bearing. These include the following basic types: Primary types:

- Single-Row Cylindrical Roller Bearings: These are the most common type and can support high radial loads. They are available in different designs, such as with or without a cage, influencing their load-carrying capacity and operational speed.

- Double-Row Cylindrical Roller Bearings: This type of bearing can bear even more radial loads and enhance rigidity, which is helpful in areas where space is constrained but a large load is needed. They also provide an enhanced load distribution and can withstand certain axial movements.

- Multi-Row Cylindrical Roller Bearings: Bearings of this category are mostly used in heavy machines with two, three, or four rows of rollers to accommodate extremely high radial loads. They are typically used in rolling mills and other heavy industrial applications.

It could be noted that there is a performance-oriented cylindrical roller bearing system for every load, speed, and operational requirement.

Usage of cylinders roller bearings in the industry

Cylindrical roller bearings are critical in many applications throughout the industry because of their capacity to carry high radial loads while enabling rapid motion. In the case of electric motors, these bearings are helpful to maintain an efficient operation even with the high stresses resulting from rotation during use. These bearings are also widely used in the construction industry cranes and other lifting devices because of their durability, good support of heavy loads, and minimum chances of failure. Moreover, in the steel & paper industries, these bearings are also used in rolling mill roll necks and paper-making machines where these elements’ accuracy and durableness are required. As for versatility, they are helpful in gearboxes, pumps, and wind turbines working under high loads and extreme conditions as well as transferring power efficiently. Looking deeper into industries where cylindrical roller bearings are used, these bearings can be found in railroads and automobile sectors inside engines, transmissions, and wheel hubs.

How Do Long Life Cylindrical Roller Bearings Enhance Load Capacity?

The influence of extreme load on performance

The limit load in roller bearings is one of the factors that helps assess the extent to which the application and performance of bearings can be optimally judged. Limit load is fundamentally dependent on the construction of the bearing, materials of the bearing, and the accuracy of its parts. Dynamic load rating is one such factor which says how much load can be carried by the bearing whilst it is rotated to a given number of rotations. However, Static load rating is the highest load that the bearing can sustain without turning, which is essential in situations where deep-seated bearing may not inch for a prolonged period yet there are heavy loads on ede. Achievements in materials and fabrication processes (e.g. high accuracy turnings and other techniques) have improved performance for cylindrical roller bearings beyond the previous limits. Optimization of roller profile and cage design also allows more uniform masses in the regime and/or fewer stress singularities, leading to longer life and more reliable bearings.

Effect of High Load Bearing Capacity on the Performance of Heavy Machine

Due to prolonged working under heavy loads, the high load-carrying capacity of cylindrical roller bearings improves machinery performance concerning wear and tear. Such bearings alleviate the incidence of mechanical port failures and minimize the wear and tear of the mechanical constituents of the machinery. This helps in reducing maintenance costs and enhances productivity. Due to their high load-carrying capacity, the bearings can withstand higher shock and impact, which is critical in heavy-duty applications. By maintaining high operating parameters, even in extreme and extreme circumstances, these bearings promote the steady performance of the machines, which leads to enhanced service life and productivity.

Differences Between High Load and Standard Capacity Bearings

As the name suggests high load capacity bearings are designed to support much higher load than standard capacity bearings. These bearings usually use state-of-the-art materials, optimally shaped roller profiles, and stiff bone structures to more evenly divide the stress and minimize the concentration of loads. Therefore, they are more robust, last longer, and perform better in tough worharshconditions. However, standard capacity bearings withstand maximum moderate load and, ,thus are designed for usage in standard machinery where no specialised or exceptional load-bearing capacity details are harshly called for. High load capacity bearings are able to be used under tough working conditions since they enhance the reliability of the machinery and reduce downtime. On the other hand standard capacity bearings are cheap and used in less harsh conditions.

What Factors Contribute to the Longevity of Cylindrical Roller Bearings?

Maintenance Practices for Longer Operating Life

Routine maintenance is going to be the key in increasing the operating life of a cylindrical roller bearing. Regular lubrication has to be done in order to reduce friction and wear, which really shortens life of the bearings. If the proper lubricant is used in every situation and the right amount is given, overheating and contamination problems can be averted. Periodic examinations to look for physical damage, misalignment, and signs of wear also need to be carried out. A major breakdown rarely happens without being preceded by precursors, and these precursors can and must be dealt with. Furthermore, a clean workspace and inner sleeve protection will guard the lubricant as well as the bearing against harmful particles which may lead to their premature failure. Correct handling and installing techniques also assist in prolonging the life span of the bearing since unnecessary stress and wear will not be inflicted during the installation process.

Significance of Lubrication in the Life of the Bearing

Excessive friction can easily be avoided by lubricating the bearing, which also reduces wear. Lack of proper lubrication subjects the rolling elements to lumps, which induces direct contact between metals and unnecessary heat. Choosing the right lubricant type, either oil or grease, according to design parameters and working conditions of a bearing, provides design usage conditions. Lubrication regimens also assist the bearing machinery in retaining its physical characteristics; the minimize the probability of wear out, and extend the bearing’s lifetime. Furthermore, good heating-lubrication-cooling practices also reduce overheating, avoid corrosion, and block foreign material from protected bearing surfaces, which may contribute to bearing failure. These advantages would only be claimed to be more understood without definition,, and regular monitoring and re-lubrication will only help enhance the bearing longevity further.

Material Quality and its Impact on Service Life

Bears’ service life and performance are highly affected by the quality of materials used in them. High-end materials, like steel and ceramic, have better strength, wear and corrosion resistance and durability than other common materials. These traits are necessary to lapse the operating forces and exposure that the bearings experience. Enhanced materials offer lower risks of fatigue and failure, allowing longer and more efficient bearings operation. In addition, exacting production processes help sustain specific material characteristics’ uniformity and consistency during and after production to give the desired reliability. Without a doubt, the bearing devices’ longevity can be improved simply by using high-quality materials and modern manufacturing capabilities.

How to Choose the Right Cylindrical Roller Bearing for Your Application?

Inclusion of Design Parameters for the Selection of Bearings in Aziz Engineering

While choosing bearings for heavy radial loads, certain considerations have to be made, and without them, performance and lifetime may be difficult challenging. The first in the ranking is the determination of the bearing load capacity. This is achieved when the static and dynamic load ratings are properly understood, which explains the bearing characteristics when the working conditions are variable, or a static load only is performed. The second one is concerned with the design and heat treatment of the bearing. Thermal and mechanical enhancements provide metal and ceramic bearings with improved properties and increase their resistance to mechanical and thermal stress. At times, the rated precision of the components is extra fine for applications with excessive loads. There is also the requirement to assess the requirements of lubrication both in terms of quantity and quality. The latter is very important in friction surfaces since it helps prevent contacting surfaces from well lubricated from overheating due to friction and prevents foreign materials from entering the bearings. A good understanding of these aspects will make it easier to choose the appropriate cylindrical roller bearing to be loaded with a radial load.

Choosing Between Tapered and Spherical Roller Bearings

When weighing the options as to whether one should choose tapered roller bearing and spherical roller bearing, it is important to put the needs of the application into perspective. Tapered roller bearings enable to accommodate radial and axial load, radial loads being those applied perpendicular to the bearing axis and axial loads those occurring along the axis of the bearing, hence probably good where forces are applied slant-wise. Due to their ability to bear scalloped loads and to offer high case of high capacity, these bearings find applications in automotive and other industrial machines.

Spherical roller bearings however are made to accept misalignment of bearings and can carry large radial loads and moderate axial loads in tension and compression. These are used in quite many industries including mining, paper mills, and naval work where misalignment and shaft deflection are predominant. Such types of bearings are used in performance of duty where there are high operation and high temperatures.

In conclusion, it is prudent to go for tapered roller bearings for those application where high axial load capacity and attention is required in alignment and loading correction precision and go for spherical roller bearings for heavy radial loading application under alignment neglects.

Advantages of Full Complement Cylindrical Roller Bearings

Displacement of a specific roller leads to the formation of a cage-free cylindrical roller bearing known as full complement assortment cylindrical roller bearing. This arrangement presents certain advantages. First, these bearings have greater structural efficiency in radial load capacity than the standard cylindrical roller bearing. Their structure is also highly stiff and precise, which is important in applications that require tiny axial displacements and high system stiffness. In addition, these types of bearings work particularly well in conditions with limited lubrication, considering the larger contact area with the rollers. Full complement cylindrical roller bearings,, help solve the problem of maintenance-free operation of equipment used in heavy-duty machines, such as industrial gearboxesand crane sheaves, as well as steel mills’ equipment where strength and confidence are essential.

What Are the Common Applications of Long-Life Cylindrical Roller Bearings?

Application in Gearboxes and Transmission Systems

In my experience, the long-life cylindrical roller bearings find application in gearboxes and transmission systems, as they exhibit great load-carrying ability and long service life. These rollers take up most of the high radial and axial loads present in the bearing arrangement when axial drilling is performed. Their structural elements retain the precision of work and texture in operation, which reduces the wear and strain of gearbox parts and components. In addition, due to the bearings’ ß reliance on the amount of lubricant in the environment, it broadens the gears and transmission systems application fields, which also helps extend the efficient service period.

Use in Rolling Mills and Heavy Industrial Machinery

In my experience, long-life cylindrical roller bearings are essential in rolling mills and heavy industrial machinery. Their resistance to excessive radial loads and harsh work environment makes them necessary. These bearings guarantee the efficient operation of heavy machines that often endure enormous stresses and strains. Their maximum contact area between roller and other bearing elements improves their performance end reliability, which is crucial to reducing production delay and upholding the working efficiency of heavy-duty applications such as rolling mills and another industrial machine.

Avenues in Linear Systems and Other Complex Equipment

As a practice, round cross-section radial roller bearings are necessary components of linear systems and other high-precision machinery. These bearings are also developed for accuracy and reliability in situations with high demand for accuracy. The increased load-carrying ability of the bearings makes it possible to have smooth and fast linear movement. This is important for CNC and optical devices, which are high-precision machines. In addition, the low friction and small play ensure that the position accuracy and position repeatability, essential in these systems, are retained. Therefore, the chronic fatigue cylindrical roller bearings enhance sustaining effective performance in linear and high-precision systems and equipment over the long term.

Reference sources

- Thermal Characterization of Cylindrical Roller Bearings: This study explores the thermal-structural coupling approach to avoid slipping, which is crucial for bearing longevity. Read more here.

- Remaining Useful Life Prediction of Rolling Element Bearings: This research uses machine learning to predict the remaining useful life of bearings, demonstrating the feasibility of advanced predictive models. Read more here.

- Influence of Roller Defect on Bearing Performance: This paper examines how defects in rollers affect the performance of cylindrical roller bearings, providing insights into durability and reliability. Read more here.

These sources should help validate the feasibility and performance aspects of long-life cylindrical roller bearings for your readers.

Frequently Asked Questions (FAQs)

Q: What are NSK cylindrical roller bearings, and what advantages do they offer?

A: An NSK cylindrical roller bearing is a high-performance bearing that can bear considerable thrust under a wiper so that the bearing deforms little. It is small in size and ecologically efficient than conventional ball bearings in that it has a longer service life and maintenance intervals.

Q: Why are NSK cylindrical roller bearings design features said to improve the performance of the bearings?

A: The features of NSK cylindrical roller bearings design, consisting of the cage’s high grade and the optimized roller geometry, determine their high loading capacity and efficiency. These bearings are made to control axial loads in a single direction and perform steadily over long periods.

Q: How critical is the ‘X-life’ quality applied in NSK cylindrical roller bearings?

A: The NSC cylindrical roller bearing ‘x-life’ quality classification is designed for high performance. This means that the bearings can all work under high loads for more extended periods lower friction and temperature stability, and everything, improved reliability.

Q: Are NSK cylindrical roller bearings interchangeable with tapered roller bearings?

A: That’s right. Apart from a special type of NSK cylindrical roller bearing, most can be adapted to replace the tapered roller bearing where most normal circumstances require radial loads. However, the bearing configurations and the functionality of the equipment must be considered.

Q: What are the standard sizes for Nokia cylindrical roller bearings?

A: NSK cylindrical roller bearings are sold in a wide range of sizes, usually denoted in mm. It is very important to choose the correct dimensions for the equipment so that it will fit in and function as intended.

Q: What are the standard safe operating practices to ensure that NSK cylindrical roller bearings are not damaged during usage?

A: In terms of NSK cylindrical roller bearings, the proper methods of use should include regular assessment and replacing of some of their parts at definite periods. Regular maintenance also involves inspection of wear parts, lubrication service and alignment to prevent failures.